Galvanized vs other corrosion resistance coatings. We talk about the difference between galvanized and black oxide coatings. Click here to read about PTFE studs!

- Where do you See Galvanized Steel Fasteners?

- What is Galvanization?

- What Type of Galvanized Process is Common?

- What is the Difference Between Galvanized Steel and Bolts Coated with Black Oxide?

Where do you See Galvanized Steel Fasteners?

Galvanized Fasteners have been in the industrial world for a long time, and I had no clue what to do with them! We see them as fasteners that we can use with flanges, standard fasteners (metric and imperial sizes), Hex Bolts, and Hex Nuts.

But here are some facts that I didn’t know:

- We don’t see them on flanges as much as we see them on everyday items such as Eye Bolts, U-bolts, structural bolts, carriage bolts, lag screws, rivets, washers, and even self-tapping studs more often than not.

- We see Grade A and Grade 2 are the most common grades of zinc-plated alloy steel for galvanized bolts and galvanized nuts (which looks like a yellow zinc coating). But while not very common it is a practice to galvanize “black bolts” or regular B7 material.

- While galvanized steel fasteners are high-strength studs that have the same tensile strength as regular studs, they have, from what I have been told, high corrosion resistance and higher durability with corrosion resistance and rust resistance.

- Apparently, over time galvanized fasteners have corrosion resistance around chlorinated water. Still, stainless steel (or other high alloy steel) is better for corrosion resistance around saltwater and other marine environments.

- Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel. The higher price for stainless steel fasteners and stainless steel nuts comes from the process of making stainless.

- Stainless steel bolts are formed when the raw materials of nickel, iron ore, chromium, silicon, molybdenum, and others, are melted together.

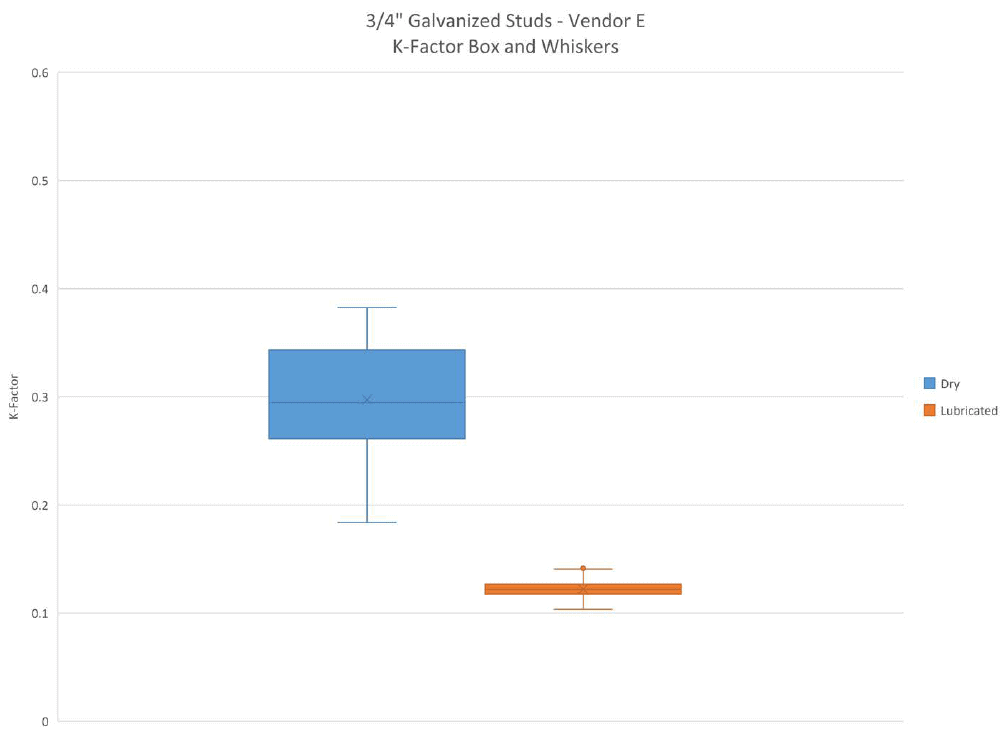

But our biggest lesson on hot-dip galvanized steel fasteners this year is that you MUST lubricate them! From our testing, the K-factor without lubrication is all over the board.

You can see in the image above that you have a high k-factor with a lot of bolt scatter if you do not lubricate them properly!!

If you would like more information on k-factor testing of galvanized fasteners, please contact us at [email protected].

What is Galvanization?

So what is Galvanization?

Wikipedia states that galvanization or galvanizing is applying a protective zinc coating to carbon steel or iron for corrosion resistance. The most common method of galvanization is hot-dip galvanizing, in which the parts are submerged in a bath of a molten hot layer of zinc.

Hot-dip galvanizing is done by placing the fastener in molten zinc at 842°F, and “the pure zinc (Zn) reacts with oxygen (O2) to form zinc oxide (ZnO), which further reacts with carbon dioxide (CO2) to form zinc carbonate (ZnCO3)” – Wikipedia.

What Type of Galvanized Process is Common?

Everyone I dealt with for galvanized fasteners in flanges states that you should use only one type of fastener: Hot-dip galvanized steel.

So the first question racking my brain is how many different types of galvanizing are there?

There are different types of galvanization, including:

- Hot-dip galvanization – immersion of the item in molten zinc

- Continuous galvanizing is a form of hot-dip galvanization, but it has a thinner zinc layer and less corrosion resistance.

- Electroplating – using the item and zinc metal as electrodes in an electrochemical cell

FYI: ASTM F2329 is the specification covering hot-dip galvanized fasteners, and ASTM F1941 is the specification covering zinc plated fasteners.

What is the Difference Between Galvanized Steel and Bolts Coated with Black Oxide?

Black Oxide is the converting of a ferrous material with a chemical treatment. Treating fasteners with a black oxide coating adds a soft layer of corrosion resistance.

We talked with a fastener manufacturer, and they stated that most fasteners come from overseas, so this black oxide is used more for rust resistance.

Apparently the studs sit on a dock in Asia for a month, travel overseas for three months, sit on a dock in America for one month, then come to the plant and sit on the shelves for 3+ months. Because of this shipping process, you can start to see some rust, so manufacturers added black oxide for rust resistance.

So if you have silver studs, they are most likely made in the USA, while the black oxide studs are made overseas!

From what we have been told, black oxide is not great for corrosion resistance, and that is why you use galvanized steel. However, for regular rust resistance, black oxide is excellent!

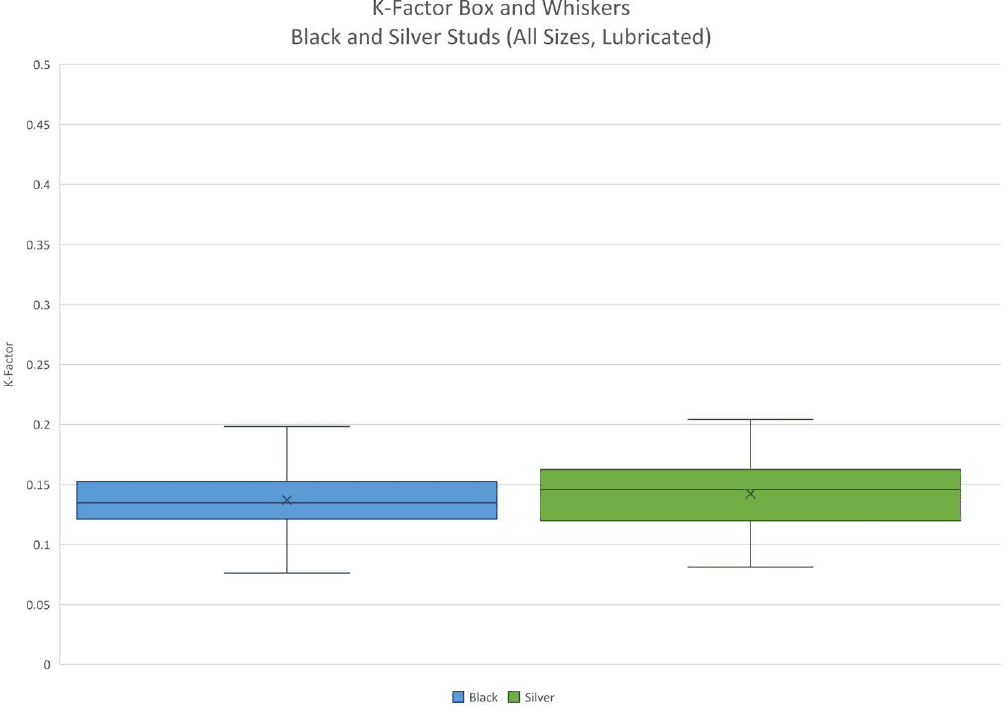

We did a study on the k-factor difference between lubricated black oxide and lubricated bare steel fasteners and found no significant k-factor difference between the two!