Corrugated Metal Gaskets (CMGs) are gaskets that we see a lot in heat exchangers where we see plenty of radial shear. Typically, we suggest the use of Kammprofile Gaskets in heat exchanger applications, but but because of the volume of use that we see in applications, we’re going to cover the details of Corrugated Metal Gaskets.

What is a Corrugated Metal Gasket (CMG)?

Corrugated Metal Gaskets can be used in specialty flanges such as heat exchangers. Still, CMGs should not be used in piping flanges (standard ANSI flanges) without proper engineering consideration. Even with engineering consideration, we still suggest using better sealing products such as spiral wounds or kammprofile gaskets instead of corrugated metal gaskets!

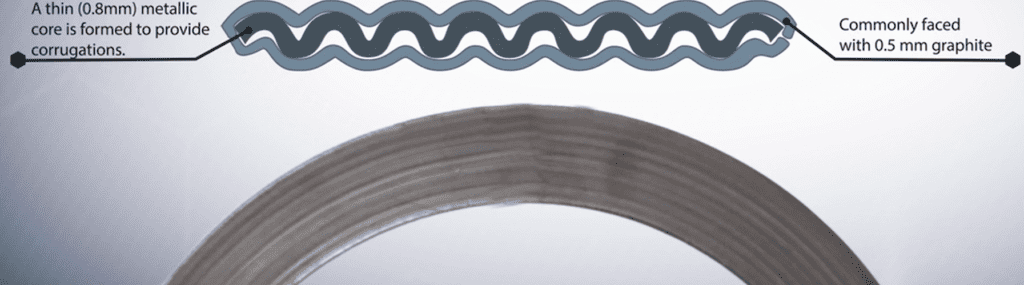

They’re a sheet of metal that’s manufacturers corrugate to make the corrugated metal core. The gasket should be used with a soft facing which essentially means flexible graphite (that’s what the gasket companies call it, we call it graphite), or another filler material like PTFE on each side.

The corrugated metal core can be made with regular gasket materials such as carbon steel, 304 stainless steel, 316 stainless steel (if you need to go to higher temperatures), and other high-temperature materials.

The filler material typically has a have graphite facing. Other non-asbestos fillers can be adapted to this gasket, but in petrochemical applications, we only see the graphite facing.

While we are not overly familiar with the use of corrugated metal gaskets outside of petrochemical applications, many companies state that these are also made with compressible sealing elements designed to resist high temperature, corrosive chemicals, and thermal cycling.

Note: We will not be discussing – Ring Joint Gaskets (RTJs), elastomeric gaskets, compression packing, o-rings, gasket sheets, and plain graphite gaskets. If you would like to know more about these kinds of gaskets, click here.

Where not to use CMGs?

Unfortunately, some manufacturers recommend corrugated gaskets for pipe flanges instead of spiral wound gaskets. These applications are not a good idea, especially for ASME B16.5 flanges.

They are not considered superior sealing products to spiral wound gaskets because they are not as resilient to thermal cycling. This is because the recovery in a spiral wound gasket is better for pipe flanges, and CMGs are not commonly used as sealing products for these flanges.

There have been papers about how the graphite sealing element will blow out when thermal cycling, and there is no recovery. With a spiral wound gasket, the graphite sealing element is packed between the windings, and there is a better chance of re-sealing the flange.

What are the Best Uses for a CMG?

We see CMGs and kammprofile gaskets in heat exchangers and some expansion joints in petrochemical applications. The CMG is suitable for heat exchangers and expansion joints because they’re good at resisting radical shear and have a bit of compressibility and recovery.

And they would be an upgrade to double jacketed gaskets, but most petrochemical sites will standardize on kammprofile gaskets as their choice for heat exchangers especially.

We see these applied in exchangers because they’re good at radial shear because of their compressibility and recovery due to the flexible graphite.

These are good for high temperature & high-pressure exchangers since they can take 45ksi gasket stress. Of course, you would need to calculate your bolt load using ASME PCC-1 Appendix O to make sure you don’t overstress these gaskets.

CMGs did a great job filling the void back when double jacketed gaskets were the preferred gasket for heat exchangers, as kammprofile gaskets were too expensive. Manufacturers since then have done a great job in reducing the price of kammprofile gaskets over the last twenty years, making the price difference between them and CMGs negligible. Today, we see CMGs being used less and less due to kammprofiles.

For more information on this subject, please email us at [email protected].