Discussing the effectiveness and necessity of relaxation pass and start-up re-torque procedure according to industry research over relaxation behavior.

- Where do “Relaxation Passes” and “Start-up Re-Torque” (Hot torque) Tightening Procedure Come From?

- What do we Know About Bolt Stress Relaxation in Gasketed Flange Connections?

- Do you Lose Bolt Preload or Bolt Stress at All?

- Average Bolt Stress Relaxation After Bolt-Up

- What is Gasket Relaxation: Gasket Creep with PTFE Gaskets and Sheet Gasket Materials?

- Does Relaxation Happen on High-Temperature Flange Connections?

- Conclusion

What are “Relaxation Passes” and “Start-up Re-Torque” (Hot torque) Tightening Procedures?

Relaxation passes and start-up re-torquing procedures are used in specifications to help prevent leakage and increase sealing performance in ANSI pipe flanges, heat exchangers, and other pressure boundary joints.

Relaxation Pass: This is a circular torque pattern on a bolted flange joint assembly at the same torque value as the initial bolt torque, performed after a specific time.

Note: We typically perform this on a gasketed flange at ambient temperature and steady-state.

Start-Up Re-Torque (formerly known as hot torque): This is also a circular torque pattern on a bolted flange joint assembly at the same initial bolt torque value as it was assembled to, only done between 250F-450F. Be sure not to do this at high temperatures since the K-Factor (some mistakenly call this “coefficient of friction”) changes after 450F!

NOTE: Since there was confusion in the industry between hot bolting and hot torquing, ASME PCC-1 has modified the name of this process to ensure clarity between the two.

So, when do you perform a relaxation pass and start-up re-torque (hot torquing)? Are they worth every penny?

What do we Know About Bolt Stress Relaxation in Gasketed Flange Connections?

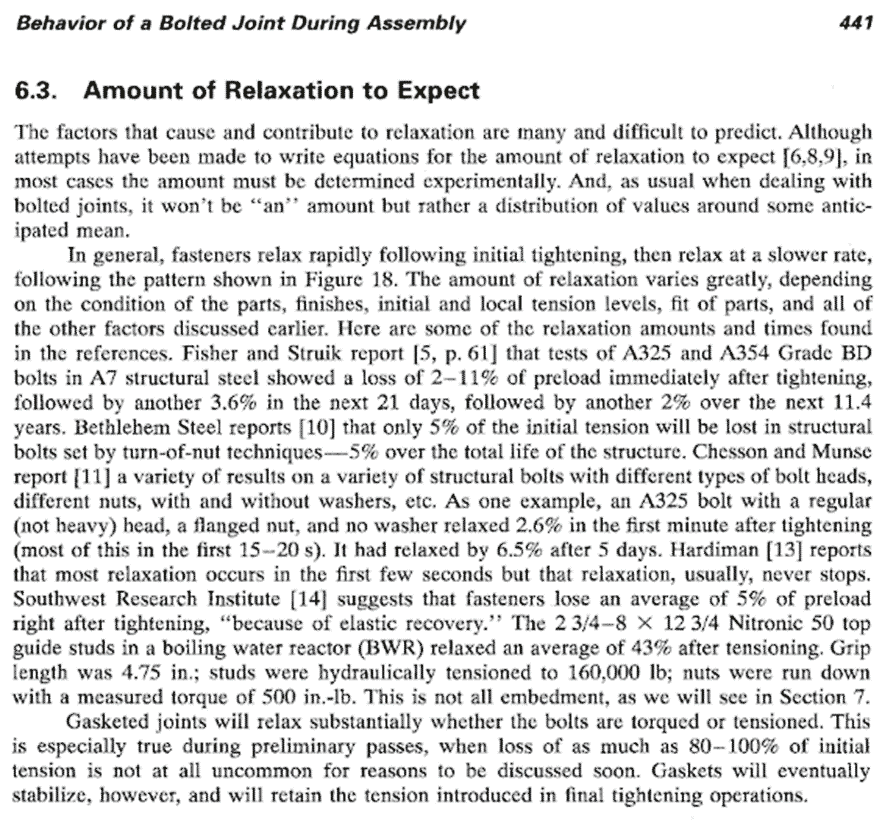

Hex started learning about bolt stress relaxation when we first read John Bickford’s “An introduction to the Design and Behavior of Bolted Joints.” John Bickford, being the grandfather of bolting.

We noticed first in the top paragraph that Bickford states experiments should be done before making a specification.

Bickford states structural steel bolts showed a loss of 11% of preload immediately after tightening and another 3.6% and the next 21 days, followed by another 2% over the next 11.4 years.

NOTE: This applies to structural steel and not a gasketed flange joint!

If you go down further, Bickford states that the Southwest research Institute suggests that fasteners lose an average of 5% of preload right after tightening in quotes “because of elastic recovery” (this shouldn’t be confused with elastic interaction).

Do you Lose Bolt Preload or Bolt Stress at All?

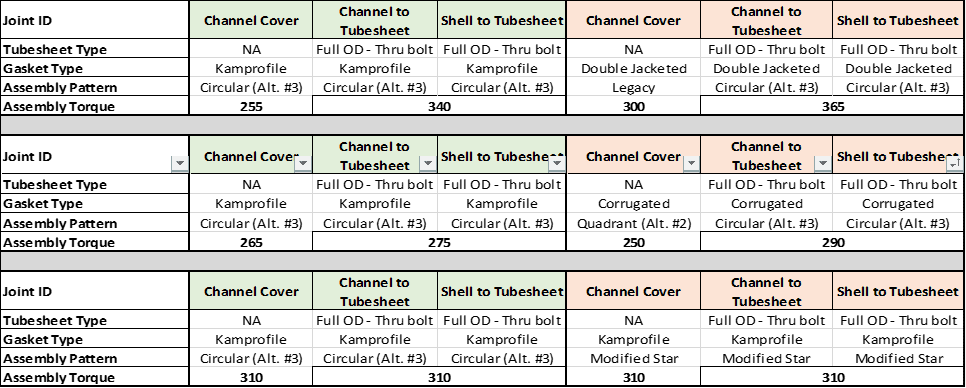

We wanted to examine how much bolt preload we might lose to bolt stress relaxation while using metallic gaskets.

A good friend of ours, who operates a refinery, said they would give us six heat exchangers with the gaskets. We used a torque wrench to do the bolt tightening. We used UT measurement to measure the axial load and monitored the amount of relaxation on the bolted flange connections.

We used three different gaskets for our test: (4) kammprofile gaskets, (1) double jacketed gaskets, and (1) corrugated metal gaskets. The experiment consisted of using UT measurements on each bolt once every hour for the first day, then once a day for six days, and then once a month for the next two months.

Average Bolt Stress Relaxation After Bolt-Up

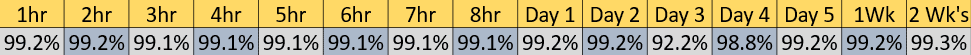

Now we get a chance to look at the data:

Suppose you look at the measurements in the first eight hours, about 0.9% preload relaxation. You’ve got to remember that UT is plus or minus 3%, so we’re well within that 3%. We also see the same readings on day one, day two, and even though two weeks of monitoring.

On average, we saw almost zero creep relaxation on metallic gaskets and no preload relaxation with standard bolt materials (ASTM B7 and B16 bolt material).

NOTE: these pressure vessels have not seen any internal pressure or high temperature!

What is Gasket Relaxation: Gasket Creep with PTFE Gaskets and Sheet Gasket Materials?

To understand this more, Hex had to go over to our friends at TEADIT and ask them to do some research on relaxation since we know sheet gaskets have gasket creep.

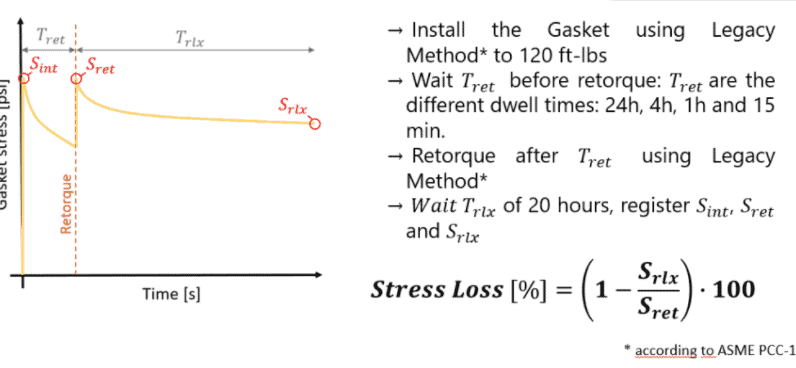

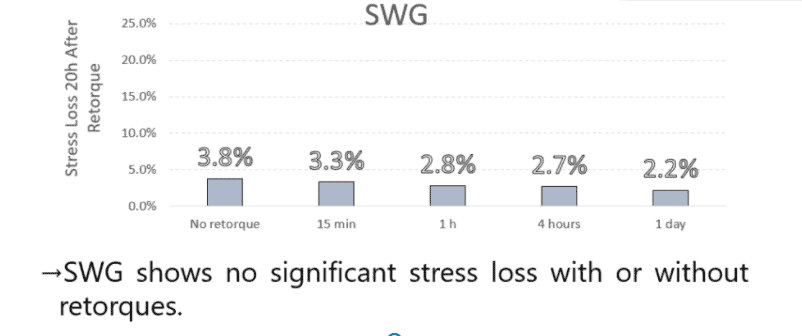

Jose Vega and his team at TEADIT went through and looked at when we should do relaxation passes. They used a 4″ 300# flange connected to software that shows the bolt stress on each of the bolts, measuring the bolts’ stress so we can measure relaxation.

TEADIT set the torque wrench to 120 foot-pounds and monitored the gasket relaxation. They performed a re-torque and then waited another 20 hours to record the gasket relaxation.

You can see these re-torque increments are:

- 15 minute re-torque – then wait 20 hours to measure the bolt stress

- 1 Hour re-torque – then wait 20 hours to measure the bolt stress

- 4 Hour re-torque – then wait 20 hours to measure bolt stress

- 24 Hour re-torque – then wait 20 hours to measure the bolt stress.

These are the results:

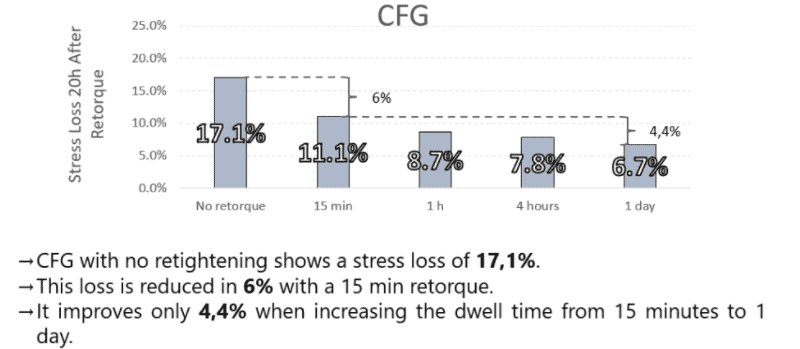

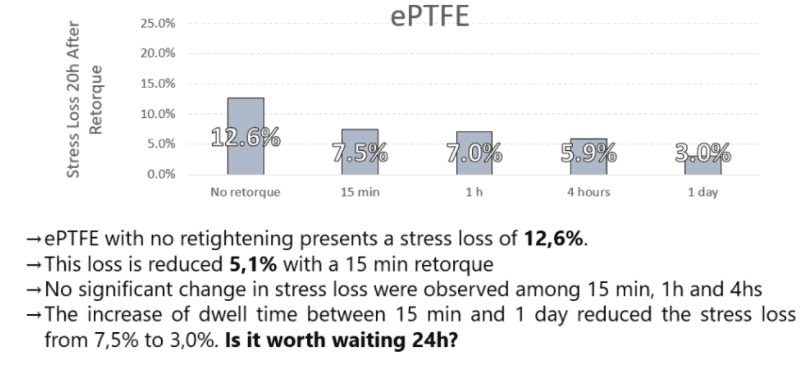

As you can see, the corrugated flexible graphite and PTFE gaskets do need a re-torque, while the spiral wound gasket doesn’t! This is because of the effect of gasket creep on the gasket thickness between the flange faces. We tend to call this “cold flow” for sheet gaskets.

You can see that after the 15 minute re-torque, you make up a decent amount of bolt stress back.

However, it is interesting that a re-torque after that gives back just a little bit (around 4%) of bolt stress and not as much reward as we thought it would.

Because of this study, Hex’s recommendation is to wait an hour, go to lunch, return, and re-torque the sheet gaskets. Another practice some refineries have that has been effective for them is to have the next shift, with re-verified torque tools, re-torque the flange.

Does Relaxation Happen on High-Temperature Flange Connections?

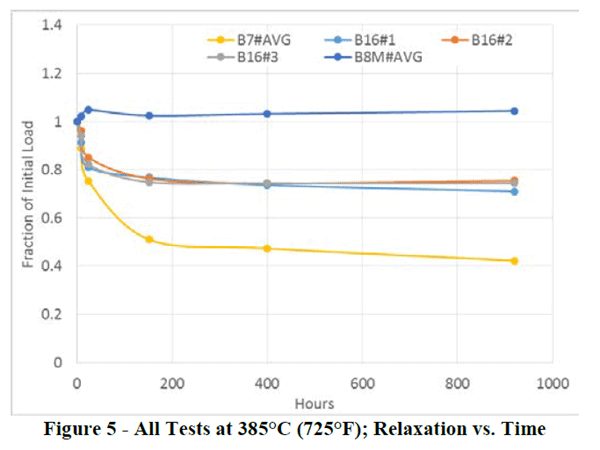

Warren Brown and Tze Lim with Integrity Engineering Solutions (a mechanical engineering consulting firm) did an excellent study, where they presented the following information at the ASME Pressure vessel and Piping Conference. Brown and Lim looked at different ASTM A193 bolt materials at 725 degrees Fahrenheit (385 Celsius) to determine how much bolt stress relaxation one should see at that temperature.

ASTM A193, B7 bolt material relaxed 60%, B16 bolt material relaxed about 25%, and the B8M bolt material gained a little load.

Most specifications in plants that Hex works with state they upgrade bolt materials between 700F and 800F process temperature. These are good for a minimum, but if you think that high temperature is a culprit for a flange connection leakage rate, my suggestion is to look at upgrading the bolt material.

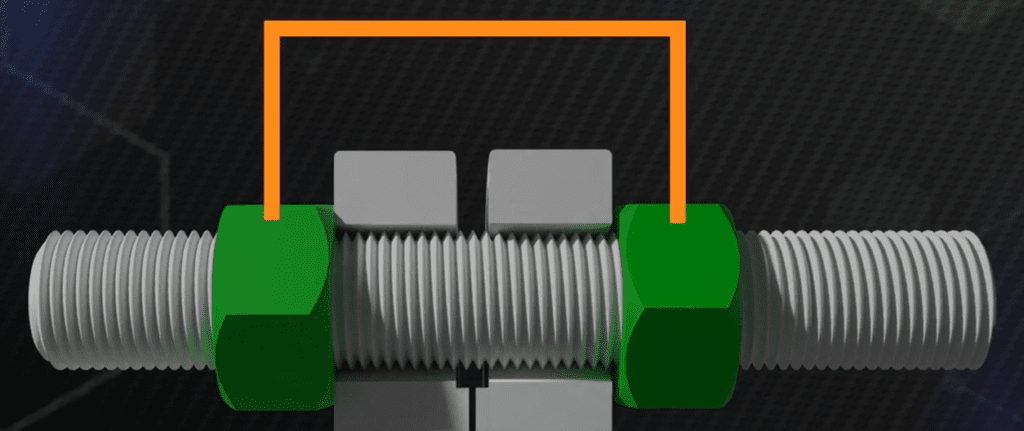

Interesting: Hex Technology has seen that some plants put Heavy Hex nuts on B16 studs instead of Grade 4 or Grade 7 nuts. That’s a bad idea as there is relaxation in the Heavy Hex Nuts that you don’t see in the Grade 4 or Grade 7 nuts.

Conclusion

Question #1: Should you do a Relaxation Pass on a bolted flange joint?

Answer: Metallic gaskets do not need a relaxation pass. The amount of gasket creep is nominal and within our margin of error for measuring with UT!

Question #2: When should I do a startup re-torque on a bolted flange joint?

Answer #2: The answer to this question has two parts.

- Part 1: I have been the guy on a live pressure vessel with a torque wrench, and it is not my favorite place. Getting a good gasket leakage buffer should be priority #1, as a slight change in gasket stress can cause a leak, and you have assemblers on the flange. So please work hard on this first.

- Part 2: Start-up re-torques on flange connections are great at 250F to 400F degrees. The reason why we put it in that semi-high temperature allows the bolt stress relaxation to start, AND your K-factor (not to be confused with the coefficient of friction) of your lubricant stays the same. At high temperatures, the oil burns off (at about 450 Fahrenheit), and your torque is no good…no matter how calibrated your torque wrench is!

We typically recommend performing a bolted flange joint analysis before making these a common task in your specification. Mechanical Engineering should look at items like flange material, operating conditions, flange rotation, and possibly even do a finite element analysis to ensure you get the correct clamping force without deformation of the flanges.

Important notes

- At the time of this article, ASME PCC-1 is working on both definitions and guidance for “Hot Bolting,” which is now called “Single Stud Replacement.”

- We did not discuss the use of washers during our experiments because they will skew the results as they increase the grip length of the studs.

For more information about relaxation pass procedure and start-up retorque, don’t hesitate to contact us at [email protected]!

See also:

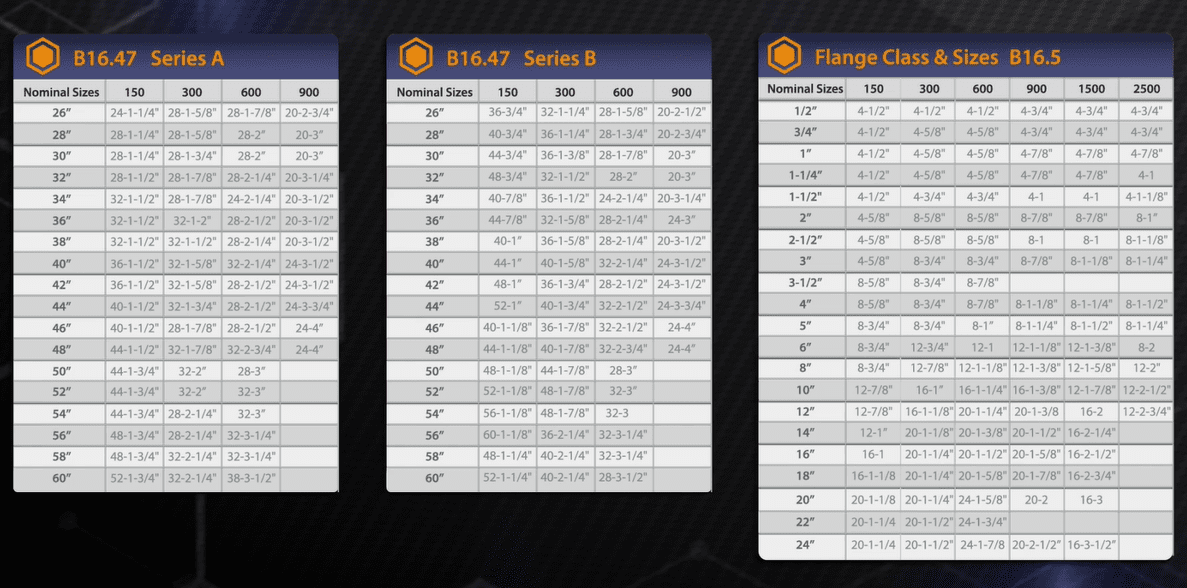

Flange Stud Bolt Lengths: What do I Need to Know?

Kammprofile Gaskets, Explained

Bolt Lubricant and Torque: A Comprehensive Guide

When we started researching PTFE studs, we took standard B7s, B7s coated with PTFE, and a set of B7 Doxsteel studs. We then put them in the worst part of a plant: In the way of drift from a cooling tower. (If you notice in the photo at left, you’ll see an icicle hanging above the test flanges.)

When we started researching PTFE studs, we took standard B7s, B7s coated with PTFE, and a set of B7 Doxsteel studs. We then put them in the worst part of a plant: In the way of drift from a cooling tower. (If you notice in the photo at left, you’ll see an icicle hanging above the test flanges.)