Academic Training

Level 1: Fundamentals

Level 1 covers the fundamentals of how to safely and properly assemble a bolted flange joint. Anyone who comes into contact with flange joints ought to learn this material.

Level 2: Assembler

The individual who has completed “Assembler Training” is capable of supervising individual crews on flanges that have been deemed intermediate.

Level 3: Supervisor/Inspector

Learn what maintenance mangers, inspectors and supervisors need to know about bolted flange joint assembly. Based on ASME PCC-1.

Level 4: Subject Matter Expert (SME)

Become your site's authority on BFJ assembly and procedures, based on the best practices spelled out in ASME PCC-1 and other documents.

Powered Equipment (Torque and Tension)

This course will teach the individual the basic methods of achieving torque and tension with the use of powered equipment, including hydraulic and pneumatic tools.

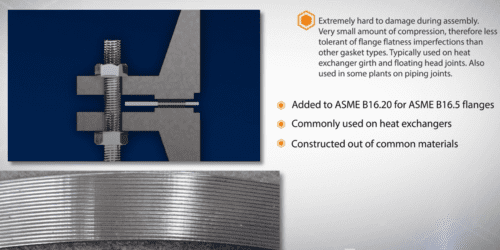

Heat Exchangers

This training discusses the basic configurations, common gaskset types, inspection, and assembly practices for Heat Exchangers.

Level 1 + Humber Refinery Training

We've coupled our Level 1 training, which covers the fundamentals of how to safely and properly assemble a bolted flange joint, with refinery-specific training required at Phillips 66's Humber Refinery in the UK. Anyone who comes into contact with flange joints at Humber ought to learn this material.